THE STORY BEHIND THE KNEEPAD THAT REVOLUTIONIZED KNEELING

An Interview with Lee E. Richards, Founder ProKnee Corp. As written by Jordan Richards Abbott, Vice President ProKnee Corp. & Daughter of Lee E. Richards

ProKnee Corp. is an American Dream success story. Built from humble beginnings by a man with a vison, this small family run business has grown into a global brand that flooring professionals around the world prefer. ProKnee is an American manufacturer of custom made custom fit knee pads specifically engineered for the floor covering installation industry and ergonomically proven to benefit the wearer through their patented designs and this is its story.

Richards on a carpet install, June 1983

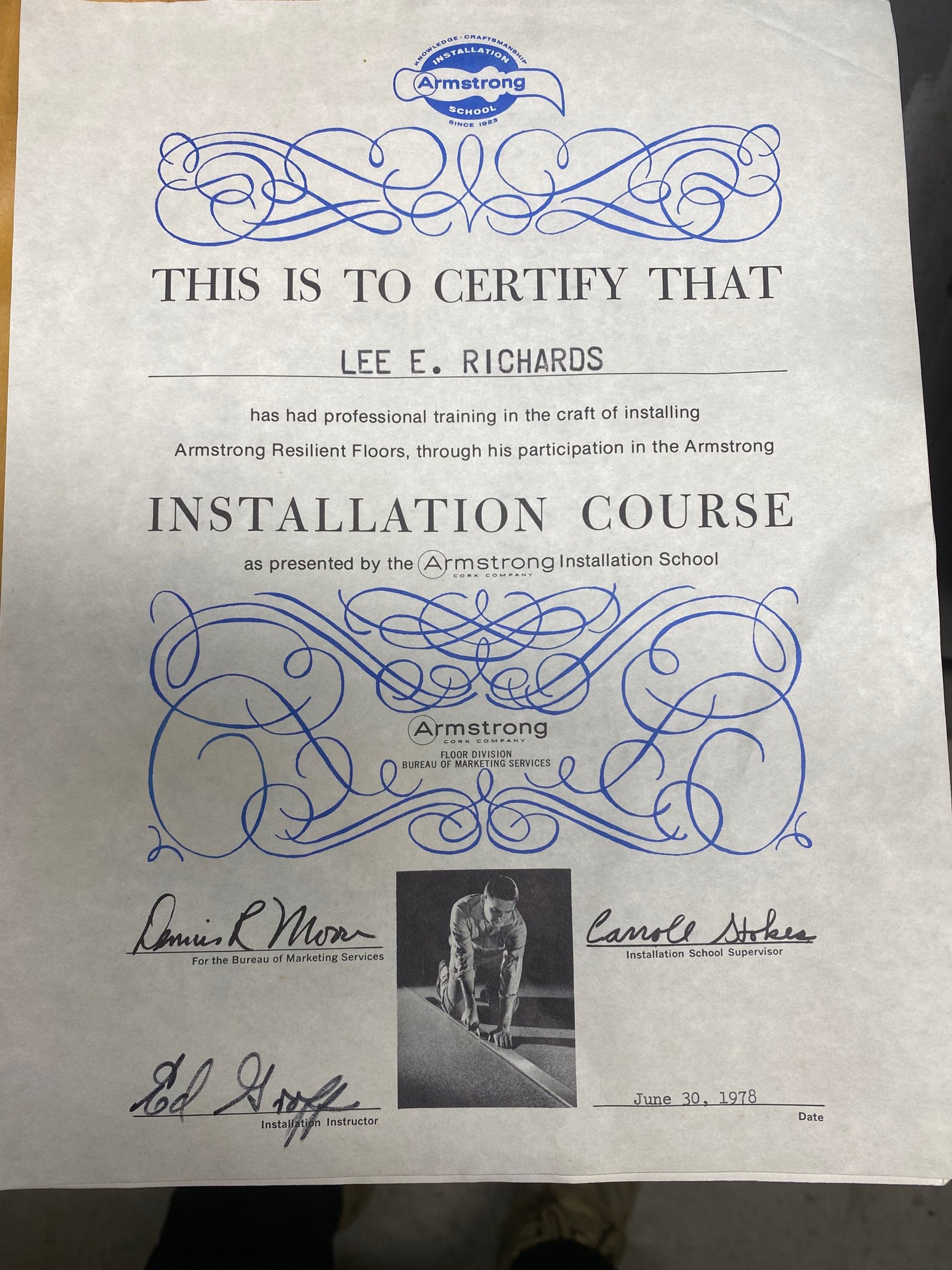

The story of ProKnee® started over 45 years ago when a self-motivated young Maine (USA) native, Lee E. Richards began a career in the flooring industry at the age of 16. Being born into a family-owned residential house-building business, construction came natural to him. After working as a warehouse person at a local flooring store, Richards decided to pursue a career of his own specializing in all aspects of floor covering installation. In 1978, he graduated from the Armstrong Installation School in Lancaster, Pennsylvania (USA). “My Instructor saw great potential in my efforts, which in turn solidified my desire to become a floor covering installation professional, an occupation I took great pride in being part of.”

Starting his own flooring installation company known as Qualified Flooring Inc. in ’83 (age 22), the extended 10-16 hour days were providing a thriving career filled with tough, yet gratifying work. However, ten years into the trade in the midst of a big job at a local ski resort, his knee became so severely swollen that he couldn’t bend it, let alone kneel on it- a typical flooring related issue related to long, strenuous hours on the knees. “After all these years the thought of not being able to do the occupation that I loved terrified me! Over the years I had used every type of knee pad available but was unable to find one that could keep me in business.” This setback challenged the longevity of his flooring career, his and his family’s livelihood and ultimately inspired Richards to create a kneepad that could keep him going. That catalyst was the moment Richards said to himself, “The money is too good in the flooring industry, and I love it. I'm going to make a knee pad that will be better than any of the knee pads out there. It's going to be designed to keep people in business, because if I am going to take the time and spend the money on the research and development, I’m not going to make it just for me; I’m going to make a business out of it.”

By 1987, Richards formed Pro Thought Products™, a division of Qualified Flooring Inc. “I was always full of ideas. The knee pad was one of probably five or six inventions I’d made by that time. In my career as a flooring installer, I always had things I was putting together to make my job easier. So when it came to forming a company, I came up with ‘Professionally Thought Products’ ie. ‘Pro Thought Products’. But the knee pad was the first commercial thing that I wanted to do. When I decided to bring this idea to market, I called it ‘ProKnee’, which I felt lent itself better to the flooring community and was simply derived from what the product was, a professional kneepad ie. ‘Pro Knee’.”

First ProKnee Prototype Model with Seat, January 1987

The first model of ProKnee utilized a seat to take weight completely off the knees and distribute that weight across the length of the shins (which it currently does today) as well as around the lower leg. This model never went to market but was the first patent Richards earned in 1988. “Technologically, it was a tough design, it required way too much money to engineer, and I needed more experience. That's not the kind of knowledge you're going to have in your head when you first start in this business. At 10 pounds apiece, it was an improbable product. I knew that the only way to make a product that was going to save the knees was to get to the guys before they had the knee problems, which is what we're currently doing. So I basically created a streamlined version of that first knee pad,” now known as ProKnee’s Original ™ Model. Leveraging several fabrications skill sets he gained when dappling with the autobody industry in high school and reading up on plastic injection technology, the development of the first prototype gave Richards the chance to work with a full range of materials and learn the molding process. He created patterns around a replica of his own leg made by kneeling into a box of flooring patch compound. “I used old school platinum silicone molding techniques to test my patterns, then modified them based off the outcome. That's how you tweak products when you don't have money, or sophisticated CAD computers.” This lengthy process took time to work through while installing full time and raising a family, so it took Richards over a dozen patterns before he confidently arrived at the design for Original Model. “Pattern making is a high-cost field that I've always decided to do myself, which I learned through trial and error.”

First pair sold made of fiberglass & resin, August 1988

Richards describes the first batches of knee pads he sold, which he produced out of fiberglass and resin at the time, “Once news got out that someone was making hand-made custom fit knee pads, I got an invitation to BIW, a General Dynamics Corporation owned company that built warships for the US Navy. This facility employed over 8000 workers of which they had a Decking / Coverings department, which installed all hull related sound proofing and coating materials. I was to observe and study the ergonomics associated with the occupational kneeling this department was responsible for and outfit them with my knee pads. Before very expensive plastic injection molds could be produced, extensive field testing had to be performed assuring all ergonomic and structural criteria had been met.” After numerous rounds of self-patterning and actual field testing, he connected with a German engineer out of Maine (USA), who specialized in plastics. After a year of work on the official mold, it was ready to be shot with plastic. “One of the most exciting things for me to ever witness were those first plastic parts. As I was looking at them, I said these parts are going to make me some money.” That aluminum mold created thousands of parts over the span of 25 years for both the Original Model and its successor, the Model 07™ and started the quest for the second tooling round in 2014 attributed to the Model 0714/0714E®, which led to several additional patents.

The original ProKnee factory, 1989

The journey to produce the Original Model knee pad was just one hurdle of many achieved in the beginning. Its patent was granted in 1989, but bringing it to market created a whole different set of challenges to overcome. Initially, ProKnee connected with a big distributor in the Northeast and did about 20 regional trade shows with them to bring the product to market. “We had super success with the product however, all the sizes made it very difficult for this distributor to handle the end transaction ie. getting the right size to the to the right customer. We concluded our business with them prematurely because customer service was very important for me to have for my customers, the end users. The sizing was a difficult situation to have with a product like this. It was high priced with multiple sizes. We knew that the installation community needed it because it was saving knees. But the only problem was getting distributors to carry that many sizes was where the learning curve needed to be had.” After another failed attempt at obtaining a distributor to carry his product, Richards said to himself, “If ProKnee is ever going to amount to anything… if these knee pads are ever going to make it in the market, then it's going to have to be a self-promotion. The product is going to have to sell itself because I can't sell through distribution. So the only other way to do it is to sell to end users.” So that’s exactly what he did.

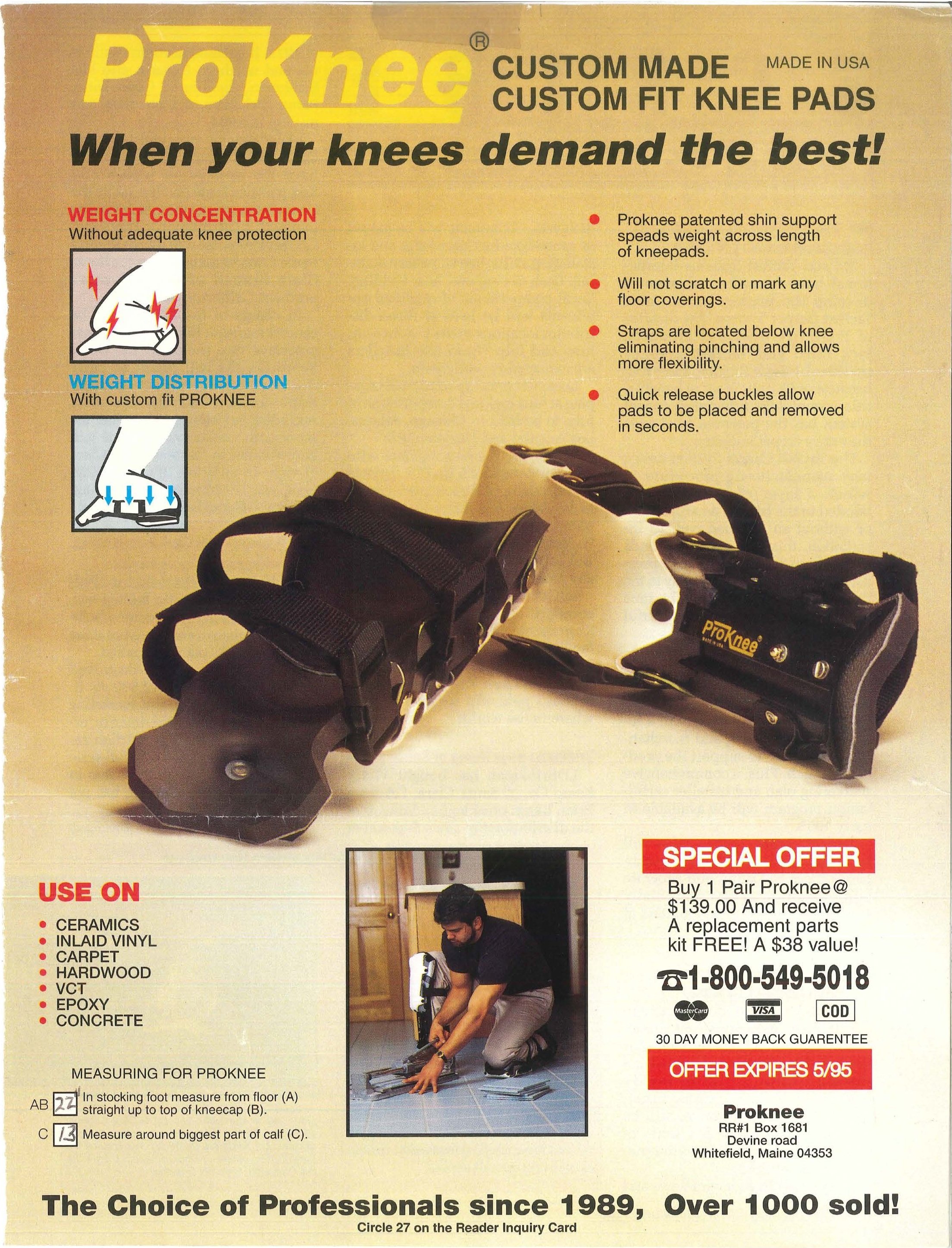

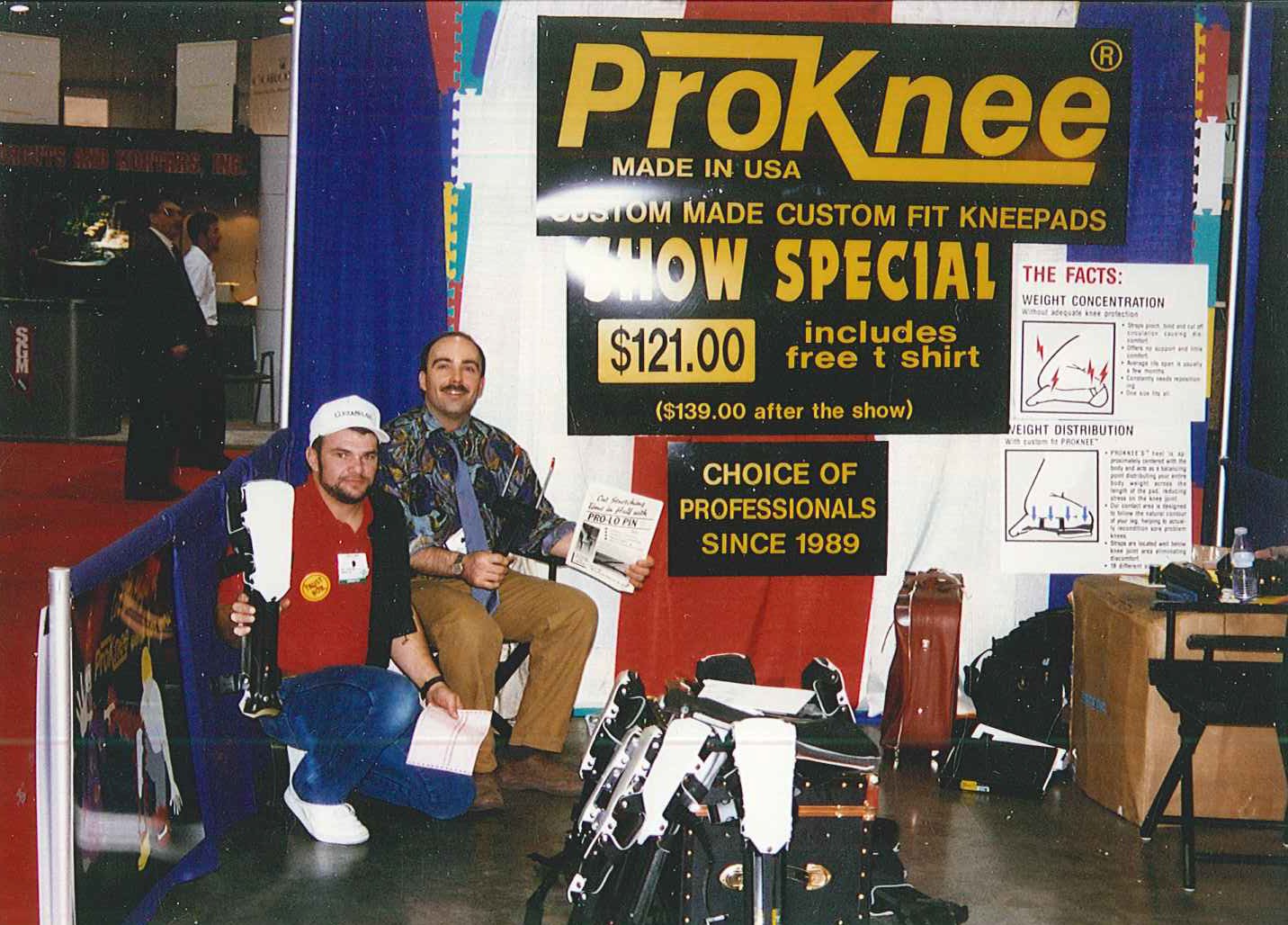

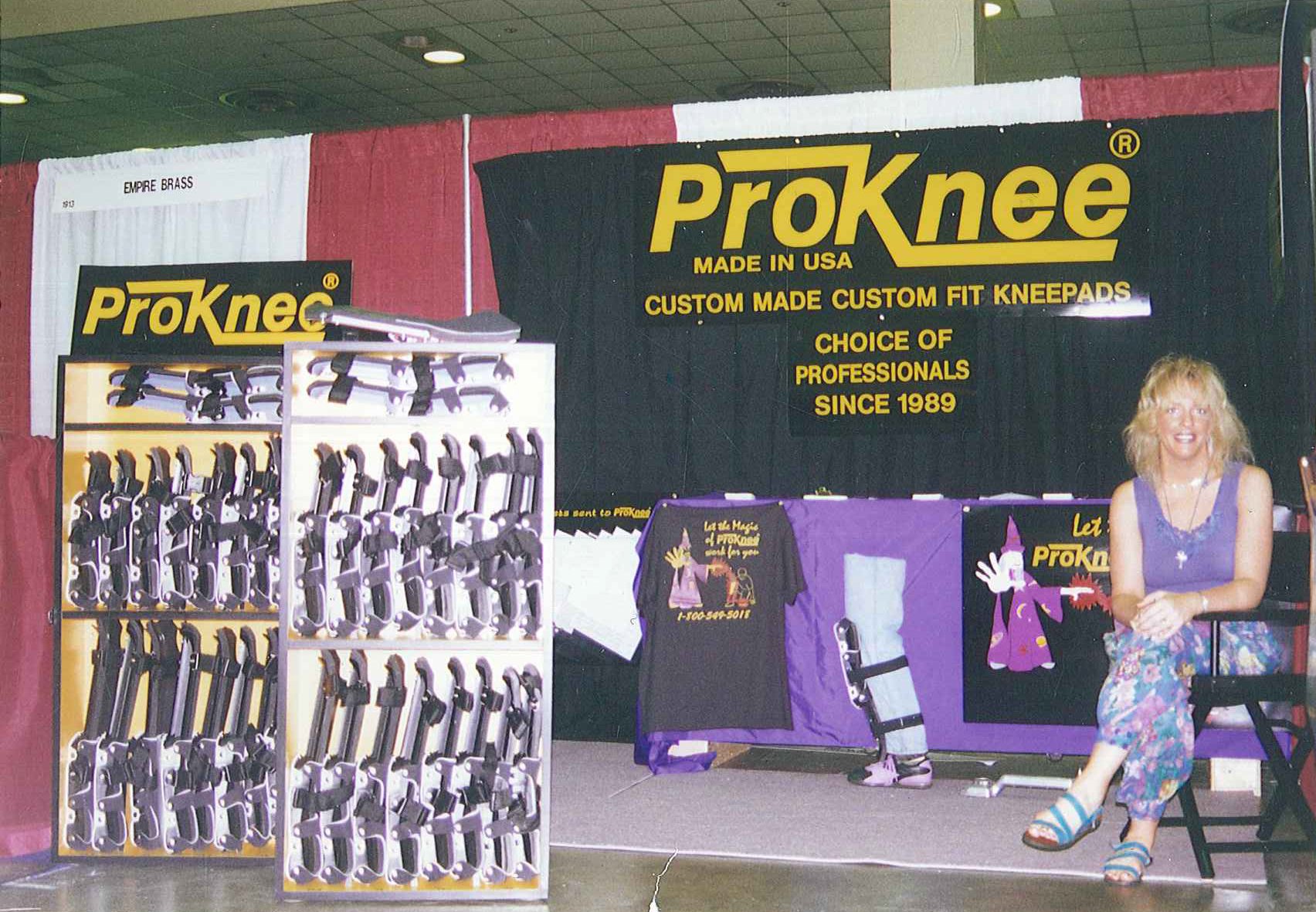

In 1995, Richards made a final attempt to bring his kneepads to market before scrapping the idea all together. Taking a bold chance and a credit card loan, he ran a full page, full color ad in Floor Covering News, an American retail flooring publication with massive circulation. “And then lo and behold…the phone started ringing. Slow at first, it took some time for sales to start off, but they started to gain momentum after the first year or so, especially after that first ad. I was figuring out that there is a way to direct market to the end user.” Then he discovered Floor Covering Installer, another American flooring publication with cheaper rates that hit his exact target audience, the installer. At the same time, the internet was in its watershed year. Richards’ brother, who specialized in information technology was the key to strategizing the development of the first ProKnee website, which was initially an information-based launch pad for phone orders. The website eventually evolved to take orders over the internet. The ‘90s saw the company through numerous tradeshows throughout the USA, notably Surfaces in Las Vegas, eliciting further exposure and acceptance. With enough market share, Richards was finally able to pick up distributors along an array of road trips and customer appreciation days peppered across the United States. “The big thing advertising proved to me was that my idea had super merit because it was reaching my market and the guys were loving the product because it was saving their knees. That's all I had to hear was the product was saving people's knees because it was saving mine; it was saving my career.”

Customer's personal collection of all 3 generations of ProKnee's custom fit knee pad, From left to right: Original Model, Model 07, Model 0714

After 24 years installing, Richards finally decided to give up his installation business, which allowed him to concentrate on growing the ProKnee brand full time. Now came production hurdles to overcome. By 2005, the company began preparation for the release of its 2nd generation custom fit knee pad, the Model 07. This version solved a cushion slippage issue by mechanically fastening the cushions to the frames that were previously adhered. He also added an Anti-Twist Cuff to the cushions, which eventually achieved a patent for the Model 07 in 2011. Additionally, Richards went to great efforts to offer the cushions in 2 thicknesses, 5/8” and 1”, to provide his customers with optimal comfort. Richards states the major catalyst for all these changes, “To make it easy for the customers to rebuild the knee pads at home. From day one, I wanted all the parts to be replaceable, so in essence ProKnee has always been about sustainability. The Originals could be rebuilt, but because everything was glued to the frame, it was quite a hurdle for the customer to do it themselves. Most rebuilds were sent back to the factory, which we were doing at no charge just to sell the parts. This created a huge amount of labor on our end, which led me to tool up our production with a laminating machine that could make our own cushions and prove concept.” After 1-1/2 years of using the laminating machine, ProKnee garnered enough sales to get a domestic supplier to invest time and engineering into the development of their cushions. “When you start to manufacture something, you're depending on another company's intellectual property to produce yours. This is the strength of doing business in the United States, of being American made.”

LJ0714 Assembly Fixture

The Model 07’s use of wire ties to mechanically fasten the cushions to the frames required drilling holes in the Original frame, which essentially solved one time consuming cog in production and added another. Growth of sales, capital and experience with the product finally afforded Richards the opportunity to make the improvements to the frame he’d wanted to do from inception. By re-engineering the frames with a new mold and further streamlining production methods, he put all efforts and capitol towards a major tool up. By 2014, Richards connected with a French engineer out of Massachusetts (USA) to execute the new mold. “I changed how the frame went together and the ease of assembly in the act. The robust nature and tensile strength of the Model 0714 frame is exactly where I wanted the frame to be structurally. Model 0714 answered a multitude of problems that we had with the Original Model and Model 07 as well as expanded ProKnee’s offering to accommodate two knee widths, standard (0714) and wide (0714E). We went from a light armored vehicle to a battle tank!” Prior models enabled the company to make enough money to keep the idea going, but the Model 0714 was designed to be very manufacturer friendly. “A big thing that drives technology need is sales. When our sales got to a point where it was costing money to make the product, the challenge was to figure out how to develop the process so that it costed less to make the product while maintaining the highest standard of quality. I put everything I had learned into this model. The more work that you can have the tool do, that's automation.” The molding process was an automated way of reducing the amount of parts, and thereby people needed to produce the knee pads, which made it most cost effective and efficient to produce. Additionally, Richards worked with his in-house machinist to fabricate the LJ0714, an assembly fixture to enable all components of the knee pad to be put together in one station as opposed moving around from station to station as with previous models. The advancements that Richards made to the Model 0714 enabled ProKnee to finally start making profit and was granted 3 patents in 2019/2020 across the US, Canada and Europe with one more currently pending.

ProKnee's current product offering, left to right: Treadman Multi Angle Stair Tread Cutting System, ProPouch, Model 0714 Standard, AP16 All Purpose Model, Model 0714 Wide, GoofProof Wall Trimmer, Over Shoulder Carry Case

By 2016, a choice to switch plastic suppliers left Richards with a destroyed mold for his Original model that was still being used on the PNAP, ProKnee’s first all purpose knee pad made exclusively for Bath Iron Works that never went to the open market. This catastrophe inspired Richards to develop the AP16, a more refined and robust version of the PNAP. “It gave me a great excuse to make another all purpose knee pad that I felt was worthy.” Utilizing live hinges that provide maximum flexibility in extreme kneeling situations, the AP16 was most recently granted its patent in 2021.

Other notable products added to the ProKnee line of industrial tools include the GoofProof® Wall Trimmer and the Treadman® Multi Angle Stair Tread Cutting System with patents granted in 2020 and 2013 respectively. Richards’ also added some accessories to the line over the years, which include a tool pouch, called the Propouch™ and an Over Shoulder Carry Case™ for hauling ProKnee knee pads. Most recently, Richards’ was granted a patent in 2022 for his development of the Smartlock® Plus Buckle, a quick release buckle that positively locks in your strap length, which enabled the company to control the process and quality of the buckles for all existing models in the line.

ProKnee’s current state-of-the-art 16,000 sq. ft. production facility in Whitefield, ME (USA) designed by Richards

By 2020, the company’s sales had outgrown its capabilities to efficiently process orders. The distribution network had grown to over 400 locations across the United States with global expansion to 7 countries, including an exclusive distributor for the UK, Floormart LTD out of Leicester. ProKnee finally had the strong distribution network it craved in its early years to transition all its direct sales to its distributors. The complications of PCI compliance and cyber safety affirmed ProKnee’s decision to close its online sales and transition the website back to an information portal.

Jay Abbott, ProKnee’s Domestic & International Sales Director & Richards’ Son-in-law, responsible for the official roll out of ProKnee’s Grab-N-Go displays

In most recent advancements, Fall of 2021 brought the release of ProKnee’s Grab-N-Go Display, an all-inclusive sales tool that allows the distributor to offer the company’s full range of products, including replacement parts for kneepads- a previous challenge that most distributors hadn’t supported until the display’s launch. This was a strategic move to ensure Richards’ customers could continue to service their knee pads with replacement parts, affirming the company’s commitment to sustainability as well as nurturing the continued growth of the company on a worldwide level.

“What means the most to me is the products that we make are helping our customers stay in the business that they love by supporting the income they're making to raise their families. Our products are directly related to the income levels of a lot of our customers, because we're making their careers easier to do and longer lasting. If you pick a trade, then you better pick items that will make you last as long as possible because if you don't do that, the alternative is you won't be doing what you love for a very long time.”

Innovation and quality are everlasting hallmarks for the ProKnee brand that will continue to inspire future generations (myself and husband included) who carry forth its legacy, a legacy that my visionary father made happen because he believed in the strength of his idea. He is living proof that dreams, with a whole lot of gumption, do in fact come true.

ProKnee standing with its Future, TISE 2020, Lee E. Richards, Founder ProKnee Corp. with Daughter, Jordan Richards Abbott, Vice President ProKnee Corp. in front of the expo booth they collaborated on